Blog

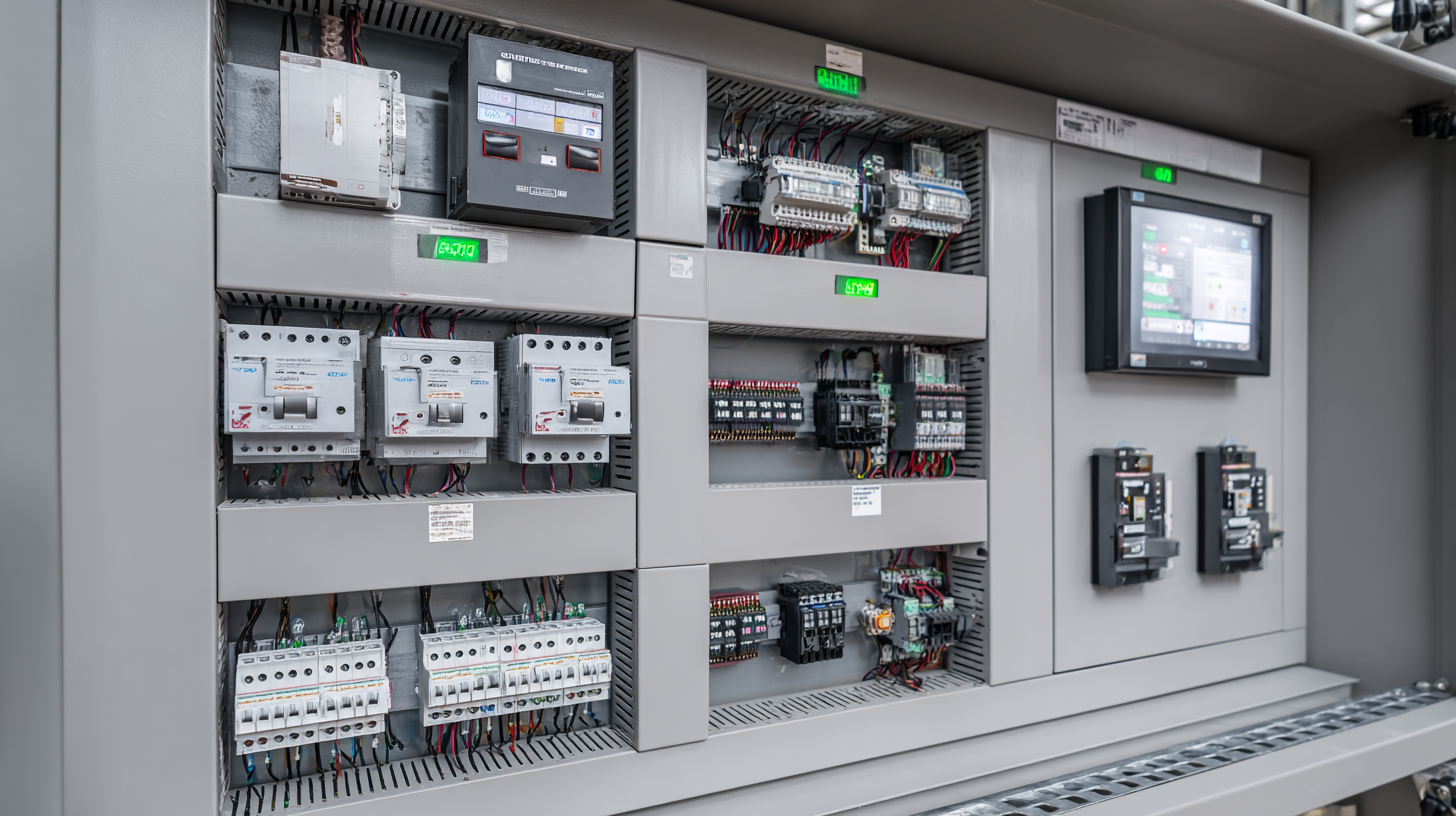

Revolutionizing Efficiency with Innovative Control Products for Modern Industries

In today's rapidly evolving industrial landscape, the demand for enhanced efficiency and precision has never been greater. Companies are continually seeking ways to optimize their operations, and one of the most effective strategies involves the adoption of innovative control products. These advanced technologies streamline processes, reduce wasted resources, and improve overall productivity, thereby revolutionizing the way industries operate.

By integrating smart control products into their systems, businesses can achieve remarkable gains in performance and reliability, ensuring they remain competitive in an increasingly global marketplace. This guide will explore how to leverage these cutting-edge control products to transform operational efficiency and drive success in modern industries, providing practical insights and strategies for implementation.

Exploring the Role of Innovative Control Products in Enhancing Industrial Efficiency

In today’s fast-paced industrial landscape, the integration of innovative control products is pivotal in enhancing operational efficiency. According to a recent report by the International Society of Automation, companies implementing advanced control systems can boost production efficiency by up to 25%. This is largely attributed to real-time data analytics and automated decision-making processes that these products enable, facilitating quicker response times and minimizing downtime. As industries face increasing pressure to optimize their processes, the role of these innovative tools becomes increasingly essential.

Moreover, a study by McKinsey & Company highlights that organizations employing sophisticated control solutions reduce their operational costs by an average of 20%. These products not only streamline workflows but also improve the accuracy of manufacturing processes, which is critical in reducing waste and enhancing product quality. With the rise of IoT and smart manufacturing technologies, the potential for innovative control products to revolutionize the industrial sector is immense. By leveraging these advancements, businesses can achieve unprecedented levels of efficiency and agility in their operations.

Key Features of Modern Control Products that Drive Productivity in Various Sectors

Modern control products are at the forefront of revolutionizing efficiency across various industries, providing essential features that drive productivity. One key aspect is the integration of IoT (Internet of Things) technologies, which allows for real-time monitoring and control of processes. According to a report by McKinsey, companies leveraging IoT solutions can achieve a productivity increase of up to 30%, significantly impacting operational costs and efficiency metrics. This seamless connectivity enables industries to gather vast amounts of data, optimize workflows, and predict maintenance needs, ultimately enhancing their competitive advantage.

Moreover, advanced automation features, such as machine learning algorithms, play a critical role in streamlining operations. Research by the International Federation of Robotics indicates that the adoption of industrial robots can lead to a productivity increase of more than 25%. These innovative control products allow for greater precision and reduced downtime, which are vital in sectors such as manufacturing and logistics. As businesses continue to embrace these modern control solutions, the alignment of technology with operational goals becomes essential for sustained growth and success in a rapidly changing market landscape.

Revolutionizing Efficiency with Innovative Control Products

Implementing Innovative Control Solutions: Strategies for Successful Integration

In implementing innovative control solutions, modern industries face the critical need to integrate new technologies seamlessly into existing systems. Strategies aimed at achieving smooth integration focus on optimizing workflows and leveraging digital tools to enhance efficiency. For instance, the use of AI-based decision-support frameworks can combine both objective data and subjective insights, allowing organizations to make better strategic choices in operational management. By streamlining decision-making processes, industries can set the stage for transformative change.

Moreover, the successful integration of AI solutions not only enhances operational efficiency but also drives innovation. Companies that adapt their business models to embrace AI experience considerable improvements in performance and competitiveness. However, this shift requires strategic human resource management to navigate the challenges that accompany technological advancements. As industries strive for modernization, the strategic deployment of innovative control products becomes paramount, acting as a catalyst for both operational excellence and groundbreaking innovations.

Case Studies: Real-World Applications of Control Products in Transforming Industries

Innovative control products have been pivotal in transforming modern industries by enhancing efficiency and productivity. In the manufacturing sector, for instance, the integration of advanced automated control systems has significantly reduced production times and minimized human error. A notable case study is that of a leading automotive manufacturer that implemented a real-time monitoring system, allowing for immediate adjustments in production processes. This innovation not only streamlined operations but also resulted in a substantial decrease in waste, showcasing how technology can lead to both economic and environmental benefits.

Another compelling example can be seen in the agriculture industry, where precision control products have revolutionized farming techniques. A recent case study highlighted a farm that adopted smart irrigation systems equipped with sensors and automated controls. This technology enabled the farmers to optimize water usage based on real-time data about soil moisture levels, ultimately leading to increased crop yields and significant cost savings. Such real-world applications emphasize the immense potential of control products in driving operational efficiency across diverse industries, reflecting a shift towards more sustainable and intelligent practices.

Future Trends in Control Technologies and Their Impacts on Industrial Operations

The future of control technologies is poised to significantly reshape industrial operations across various sectors. With the advent of advanced automation tools and smart sensors, industries are witnessing a dramatic shift in how processes are monitored and managed. The integration of Internet of Things (IoT) devices enhances real-time data collection and analysis, enabling organizations to respond swiftly to operational challenges. This connectivity not only increases efficiency but also reduces downtime, leading to substantial cost savings and improved productivity.

Emerging trends in control technologies, such as artificial intelligence and machine learning, promise to further amplify these benefits. Predictive maintenance, powered by AI algorithms, allows for more effective equipment management by analyzing historical data to anticipate failures before they occur. Meanwhile, advanced control systems equipped with adaptive capabilities can optimize production processes on-the-fly, tailoring operations to fluctuating demands. As industries embrace these innovations, the potential for increased efficiency and sustainability becomes more pronounced, setting the stage for a transformative era in industrial operations.

Related Posts

-

Exploring the Future of Control Products: Innovations Shaping Industries Today

-

Exploring the Impact of Sound Absorption Panels on Industry Trends at the 138th Canton Fair 2025

-

The Science Behind Acoustic Treatment Panels and Their Impact on Sound Quality

-

Transform Your Space with Innovative Sound Reducing Panels for Ultimate Comfort

-

Exploring Acoustic Windows Trends at 2025 China Import and Export Fair

-

The Power of Sound How Acoustic Products Enhance Our Daily Lives